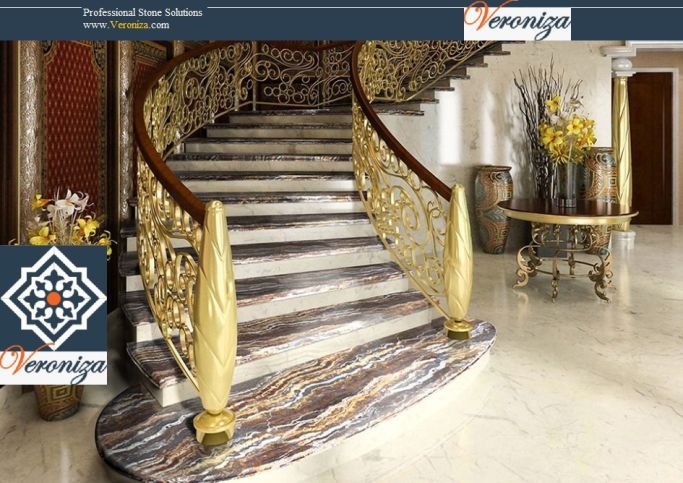

Due to the use of metals in the design of stone buildings, the company has presented various designs to manufacturers of these products to make their products more complete. You can find some of them:

Wrought Iron

Wrought iron is an iron alloy with a very low carbon (less than 0.08%) content in contrast to cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which gives it a "grain" resembling wood that is visible when it is etched or bent to the point of failure. Wrought iron is tough, malleable, ductile, corrosion-resistant and easily welded.

Wrought Iron Products

Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name wrought because it was hammered, rolled or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be hardenable by heating and quenching.

Ready Wrought Iron Products

Wrought iron is highly refined, with a small amount of slag forged out into fibres. It consists of around 99.4% iron by mass.The presence of slag is beneficial for blacksmithing operations, and gives the material its unique fibrous structure.The silicate filaments of the slag also protect the iron from corrosion and diminish the effect of fatigue caused by shock and vibration